Circular economy in the fashion industry: what is it?

The linear economic model is based on the extraction of finite natural resources, erroneously considered unlimited, to produce finished products that, at the end of their life cycle, are disposed of in landfills (take-make-use-dispose).

This model is highly polluting and generates significant pressure on natural ecosystems.

The circular economy, on the other hand, is a system solution framework that addresses global challenges such as climate change, biodiversity loss, waste and pollution.

It is based on three principles:

- Eliminating waste and pollution

- Extend the life of materials and products

- Regenerate nature

The transition to a circular economy involves decoupling economic activity from the consumption of limited resources. This represents systemic change that creates long-term resilience, generates business and economic opportunities, and offers environmental and social benefits.

The circular economic model is a valid and effective tool to mitigate the environmental impacts of the fashion industry that is responsible for 10% of global carbon emissions, more than the total of all international flights and maritime transport combined.

The high impacts of the fashion sector are also highlighted by an analysis by the European Environment Agency, according to which textile purchases in the EU in 2017 generated about 654 kg of CO2 emissions per person.

Therefore, the environmental impacts of the fashion industry are particularly significant and the circular economy could be an essential tool to improve its level of sustainability by 2030.

Textile products according to the circular economy

In order to mitigate the environmental impacts of the fashion sector, textile products must be as similar as possible to the principles of the circular economy.

In particular, in a circular economy context in the fashion industry, the products are:

- Designed to have a second life: products must be designed and created to be easily disassembled in order to facilitate recycling and reuse;

- Made from safe, recycled and renewable inputs: in a circular economy process it is necessary to design safe products. It is important to try to minimize the use of virgin raw materials, preferring the use of recycled materials;

- Used longer: Circular business models maximize the value of products, which are designed to last as long as possible. Also in this case the design phase is essential to design a product suitable for reuse.

In order to be able to design and manufacture products with similar circularity characteristics, companies must activate the following levers:

- Material analysis;

- Implementation of the circular economy in production processes;

- Distribution and sales.

Material analysis

Circular design is essential for designing a product considering the environmental impact of the garment throughout its life cycle and its ability to be disassembled and, therefore, recycled.

In this phase, in fact, it is important to select materials and production processes with the aim of creating products that can last as long as possible and that are made with processes that have little impact on the environment.

The analysis of materials makes it possible to create garments from safe, recycled and renewable inputs and designed to have a second life, through:

- Design studied to facilitate disassembly and avoid waste: which allows to reduce the quantity of elements and accessories that make up the product, reduce the quantity of elements that are not easily separable and, therefore, recyclable (e.g. zips, buttons, padding, etc…) preferring mono-material fabrics and avoiding waste through tools such as zero-waste modeling (which allows the fabric to be used in its entirety, eliminating waste in the design phase of a garment).

- Select compostable, recyclable and durable materials and minimize the use of dangerous chemicals: the choice of these categories of materials depends on the type of final product you want to obtain but it is important to underline that it is essential to minimize the use of chemicals harmful substances that could hinder recycling and composting operations.

Implementation of the circular economy in the production processes of the supply chain

As previously mentioned, one of the pillars of the circular economy consists in the elimination of waste and pollution.

Defining the circular economy as a model that only encourages recycling practices or the use of recyclable materials is very limiting.

Firstly, the circular economy aims to mitigate the environmental impacts of the sector at source, through the use of renewable energy sources. In fact, by improving the energy mix and energy efficiency during the material manufacturing processes, 703 million greenhouse gas emissions would be avoided.

Secondly, the circular economic model makes it possible to significantly reduce environmental impacts through the optimization of production processes to favor the reduction of waste and waste of materials and energy. For example, by minimizing waste in production and manufacturing, 24 million tons of greenhouse gas emissions would be saved.

Finally, the circular economy provides for a systemic approach to sustainability, i.e. a strategy that aims to reduce the environmental impacts not only of the individual company, but also of its supply chain.

In this regard, the tracking of the supply chain guarantees that the products are made from safe, recycled and renewable inputs, since every single actor in the value chain is constantly monitored. This promotes knowledge of the chemicals, processes and products used, facilitating the recovery and recycling of materials.

For example, there are various certifications that allow you to monitor the information relating to the inputs, chemicals and processes used along the supply chain, such as:

- Bluesign: Assess all input streams, including raw materials and chemicals, minimizing risks to workers, users and the environment.

- Oeko-Tex Eco Passport: is a mechanism by which chemical manufacturers and suppliers can demonstrate that their products meet specific standards, as these are screened against their MRSL and RSL guidelines, as well as REACH guidelines and ZDHC extension

- Cradle to Cradle: global standard for safe, circular and responsibly manufactured products;

- ZDHC: has defined an MRSL, a list of chemicals prohibited in production processes, with which companies must comply. To be aligned with the ZDHC MRSL, a brand must have a compliant supply chain.

Distribution and sales

The adoption of circular business models involves maximizing the value of products, since they are designed to last as long as possible.

According to the work conducted by the Ellen MacArthur Foundation “Circular Business Models” – Rethinking business models for a thriving fashion industry” there are 4 main circular business models in the fashion sector, which allow for the decoupling of revenue streams from the production and use of resources.

In particular, these business models correspond to:

- Resale: the resale service can guarantee a reduction of CO2e emissions equal to 47% compared to the linear economic model;

- Rental: B2C rental can guarantee a reduction in CO2e emissions of 41% compared to the linear model;

- Repair and Remaking: the repair service can generate a reduction in CO2e emissions of 31% compared to the linear model. With the "remanufacturing" service it is possible to double the number of times an item of clothing is used (the Ellen MacArthur Foundation within the work "Circular Business Models" - Rethinking business models for a thriving fashion industry" hypothesizes that a garment is used about 20 times in the linear economic model, while 40 with the "Remaking").

The adoption of circular business models not only guarantees environmental benefits, but also economic ones.

In recent years Resale, Rental, Repair and Remaking have grown significantly, so as to represent a market share of 73 billion dollars as of 2019.

However, according to the work conducted by the Ellen MacArthur Foundation “Circular Business Models” – Rethinking business models for a thriving fashion industry” the 4 circular business models mentioned above could be worth 700 billion dollars by 2030, representing 23% of the global fashion market.

The implementation of circular business models, however, is not that simple.

Garment rental, for example, requires that there be a wide network of customers for the company to enjoy, from the service offered, an economic benefit. It also presents logistical challenges, such as laundry service and delivery/pickup of rented garments.

In a previous article, we explored some case studies of virtuous companies that have implemented circular business models.

Conclusions

The fashion sector has significant environmental impacts such as: carbon dioxide emissions, high consumption of water and chemicals harmful to humans and natural ecosystems and the production of large quantities of waste disposed of in landfills or incinerated.

There are, however, various solutions capable of mitigating the environmental impacts of the fashion sector. Among these, the circular economy is one of the most effective tools since it makes it possible to reduce or eliminate environmental problems at the source, while simultaneously guaranteeing the economic development of companies.

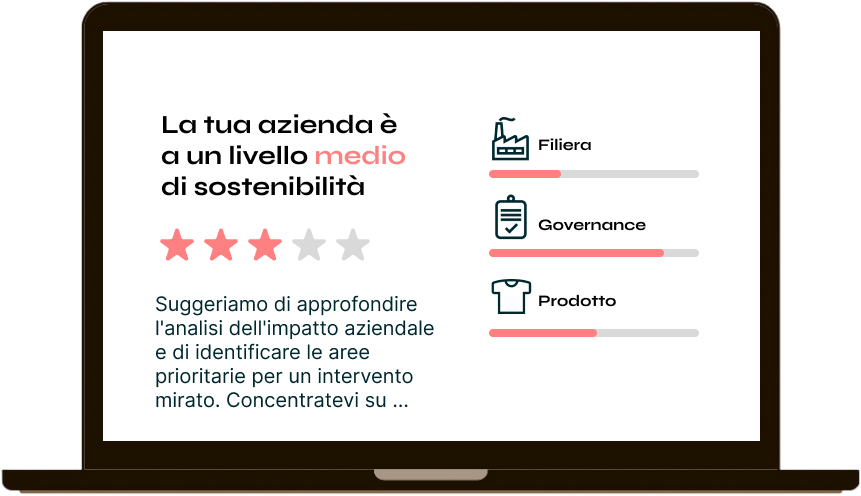

The analysis of materials, the tracking of the supply chain and the adoption of circular business models require adequate knowledge, multidisciplinary skills and above all a systemic approach to sustainability.

Cikis can help you in this since it supports companies in designing an ad hoc sustainability strategy for the company, with the aim of outlining the most effective path to sustainability.

Get articles like this and the latest updates on sustainable fashion automatically!