Interview with Comistra: regenerated wool, innovation and sustainability

Wool is a natural fiber of animal origin that comes from sheep, goats, camels, llamas and alpacas.

Wool garments have a relatively long life, as their life cycle can extend up to 20-30 years. Furthermore, wool is an easily recyclable material, even if on a global level the share of recycled wool production corresponds to only 6% of the total production.

Despite the not very encouraging data on a global level, a well-known wool recycling hub is present in Italy, in particular in the Prato district which welcomes the best excellences of our country in the production of regenerated wool.

How is the recycling process organized and what are the characteristics of regenerated wool compared to "traditional" wool?

We talked about it with Fabrizio Tesi, CEO of Comistra, a company in the Prato district that produces regenerated wool starting from the recovery of textile industry waste.

Cikis: Welcome Fabrizio, can you tell us the history of the company?

F: The company was born in the Prato district which has been involved in textile recycling for 180 years and in bringing back used garments and textile by-products that come from the waste of the yarn and fabric production plants to a second life.

Our company born in this context has a unique plant in the world for the recycling of wool.

Recycling can be done in 3 ways:

- Chemical recycling;

- Thermal recycling;

- Mechanical recycling.

In our company, we deal with mechanical recycling which for us is the most virtuous process from an environmental point of view, both in terms of CO2 emissions and water consumption.

Going back to the history of the company, my grandfather started the business in 1920 but then it was my father who founded the Comistra company in 1951, which means Commerce and Import of Rags.

The name derives from the fact that the rags came to Prato from all over the western world. And so the story began starting from the sorting of used rags, essential for obtaining a recycled product in a single colour.

After several years, with my arrival and that of my sister, in 1983, in addition to the sorting of rags, we purchased systems capable of returning used clothing to the fibrous material.

Later, in addition to the selection and transformation of used clothing into fibrous material, the company began to produce carded yarns for external sale to other customers and for use within Comistra for the production of sustainable carded fabrics.

This is, in short, the story of our family.

Mechanical recycling of textile waste: benefits and challenges

Cikis: You told us about different recycling methods: what are the advantages of mechanical recycling?

F: The aim of recycling must be not to waste raw materials, which will have to be used to renew existing stocks. Therefore it is necessary to implement recycling processes with low environmental impact and which allow secondary raw materials to be reintroduced into the production cycles.

This does not happen in the case of thermal recycling as the material is burned to generate electricity or heat, guaranteeing only a certain percentage of environmental benefit.

In mechanical recycling, on the other hand, the kilos of materials that we introduce into our process remain the same at the end of the recycling and are not lost.

Cikis: Can mechanically recycled wool be further recycled? Furthermore, to increase the recycling rate, what are the obstacles to overcome?

F: The recycling of a product depends on its design.

In our sector we can produce our yarns in 2 different ways:

Open end: method used by big brands because the costs are low compared to the self-acting system. The open end system requires very short fibers;

Self-acting system (typical of the Prato district): it requires very long fibers and this allows them to be recycled a greater number of times.

The design of the product, therefore, strongly influences the amount of recycling processes that the fibers can undergo.

This is why eco-design is important to make the product last longer and to facilitate recycling processes.

Conclusions

The global share relating to the production of regenerated wool corresponds to only 6%, however, here in Italy and in particular in the Prato district there are virtuous companies that deal with the recycling of wool.

According to Fabrizio Tesi, mechanical recycling is considered very virtuous from an environmental point of view because not only does it not waste material but it is also responsible for less water consumption and lower polluting emissions compared to other types of processes.

During the interview, a further essential aspect emerged for a more circular and sustainable fashion. Recycling processes are influenced by product design and, in this regard, eco-design is a useful tool to facilitate the management of the end of life of clothing.

The implementation of sustainability practices requires a systemic and holistic approach, able to evaluate the performance of a product "from the cradle to the grave".

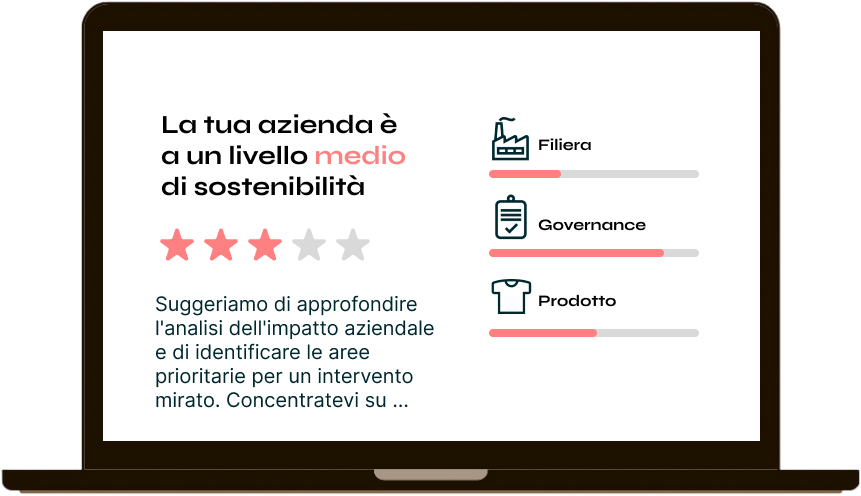

We at Cikis support companies in defining a comprehensive sustainability strategy with the aim of helping companies implement virtuous practices from an environmental point of view and adequately communicate the results achieved.

Get articles like this and the latest updates on sustainable fashion automatically!